YQN Smart WMS: Your All-in-One 3PL Warehouse Management Solution

YQN Smart WMS delivers a powerful 3pl warehouse management system that empowers you to achieve increased efficiency in logistics. You gain advanced 3pl warehouse management system features that drive scalability and accuracy. With over 60% of global shipments handled by 3pl providers, a robust 3pl warehouse management system is vital for modern supply chain success.

Effective 3pl warehouse management system solutions can reduce overhead costs by up to 10% and enhance visibility, supporting your warehouse operations and supply chain agility.

Understanding 3PL Warehouse Management Systems

What is a 3PL Warehouse Management System?

A 3PL warehouse management system helps you manage every aspect of your warehouse operations. You use this software to streamline logistics tasks and connect your warehouse with the rest of your supply chain. The system covers inventory management, order fulfillment, cost calculation, and reporting. You gain real-time visibility into inventory and order status, which lets you respond quickly to customer needs. The warehouse management system also automates many processes, reducing manual errors and improving accuracy. You can scale your operations easily as your business grows.

A 3PL warehouse management system gives you the tools to speed up processes, cut costs, and boost revenue. When you choose a 3PL partner, look for a warehouse management system that supports seamless integration with your supply chain management and logistics platforms.

Key benefits include:

Real-time inventory tracking and order updates

Automated accuracy for fewer mistakes

Flexible adjustments for stock, packaging, and transport

Enhanced customer satisfaction through quick responses

Why 3PL Providers Rely on WMS for Increased Efficiency

You rely on a warehouse management system to handle the complexity of modern 3PL operations. The system gives you the flexibility to manage different customer requirements, whether you ship electronics or food. You can configure workflows quickly and onboard new clients with ease. Advanced billing modules automate revenue recognition and prevent revenue loss. Integration with automation tools, such as robots and ASRS, keeps your warehouse running smoothly even during disruptions.

3PL providers improve efficiency by:

Investing in scalable warehouse management systems for future growth

Streamlining billing with real-time rate calculations

Managing multiple facilities under one system

Adapting workflows quickly without programming

Giving customers real-time visibility through dedicated portals

Optimizing labor and boosting productivity

You see fewer stock issues, faster reordering, and easier planning for growth. The warehouse management system helps you categorize inventory, set reorder alerts, and review stock regularly. You prioritize high-demand products for picking and restocking, which increases efficiency and customer satisfaction.

YQN logistics delivers smart warehouse management systems for North and South America. If you need warehouse services or a free consultation, contact info@yqn.com.

Key Features of YQN Smart WMS

Intelligent Palletizing Recommendations

Problem Solved: Inconsistent palletizing for identical SKUs and low space utilization

You often face wasted space and unstable pallets in your 3pl warehouse. YQN Smart WMS solves this by standardizing palletizing for identical SKUs, boosting both safety and efficiency.

Recommendation Logic: Suggests optimal pallet quantity and height based on SKU dimensions and rack type

The system analyzes SKU size and rack type to recommend the best pallet count and stacking height. This approach ensures you use every inch of space and maintain pallet stability.

Key Feature: Generates palletizing recommendation records and visual diagrams

You receive clear records and diagrams for each recommendation, making the order fulfillment process smoother.

Metric / Case Study | Description / Result | Impact on Palletizing Effectiveness |

|---|---|---|

Space Utilization Ratio | Ratio of volume of products stored to total pallet volume | Measures space efficiency improvements |

Cycle Time | Time from receiving to shipping | Reduced by optimized pallet handling |

Return on Investment (ROI) | Includes direct cost savings and indirect benefits like reduced damage | Demonstrates financial benefits of intelligent palletizing |

Case Study 1: Global Retailer | 30% improvement in space utilization; 25% reduction in order processing time | Validates operational speed and space efficiency gains |

Case Study 2: FMCG Industry | 20% drop in operational costs via IoT sensor integration | Shows cost savings and operational efficiency |

You benefit from improved accuracy, cost savings through optimization, and seamless system integration.

Intelligent Putaway Recommendations

Problem Solved: Random manual putaway leading to inefficient picking routes and frequent relocations

Manual putaway often leads to wasted time and poor picking paths in your warehouse. YQN Smart WMS eliminates this by recommending precise storage locations.

Recommendation Logic: Recommends precise storage locations by considering post-palletizing volume and weight, inventory distribution, SKU zoning, and putaway paths

The system evaluates volume, weight, and SKU zones to optimize storage. You get global optimization, not just local judgment.

Advantage: Algorithm achieves global optimization compared to manual local judgment

You see measurable gains:

Improvement Area | Benchmark / Result |

|---|---|

Picking productivity | |

Labor cost reduction | Reduced by 22% |

Storage capacity | Improved by 15% without physical expansion |

Order accuracy | Improved from 97% to 99.5% |

Customer complaints | Decreased by 60% |

Stockouts | Reduced by 70% |

Order fulfillment time | Reduced by 40% |

Inventory turns | Increased by 25% |

Daily order handling capacity | Increased by 30% with existing staff |

ROI | Achieved in less than 6 months |

You gain improved accuracy, higher fulfillment rates, and better visibility.

Intelligent Replenishment and Relocation Recommendations

Problem Solved: Disorganized layout due to goods movement, resulting in low outbound efficiency and wasted space

Disorganized inventory slows your outbound fulfillment and wastes valuable space. YQN Smart WMS analyzes hot and cold zones, rack distribution, and SKU density to suggest relocation tasks.

Recommendation Logic: Analyzes hot/cold zones, high/low rack distribution, and SKU density to suggest relocation tasks

Functional Goal: Dynamically optimize inventory layout to improve picking efficiency and space utilization

Simulation studies show inventory effectiveness improves by up to 92%, with inventory held in shops dropping by 67%. You see faster throughput and better inventory management.

Real-Time Inventory Tracking for Enhanced Visibility

You gain real-time visibility into every item in your 3pl warehouse. Companies like Amazon and Maersk use similar systems to cut expedite rates by 90% and boost customer satisfaction by 25%.

Clif Bar achieved 100% paperless tracking, improving traceability and accuracy.

Big Dee’s reduced picking and packing time by 70%, enabling same-day shipping.

Automation in Order Fulfillment

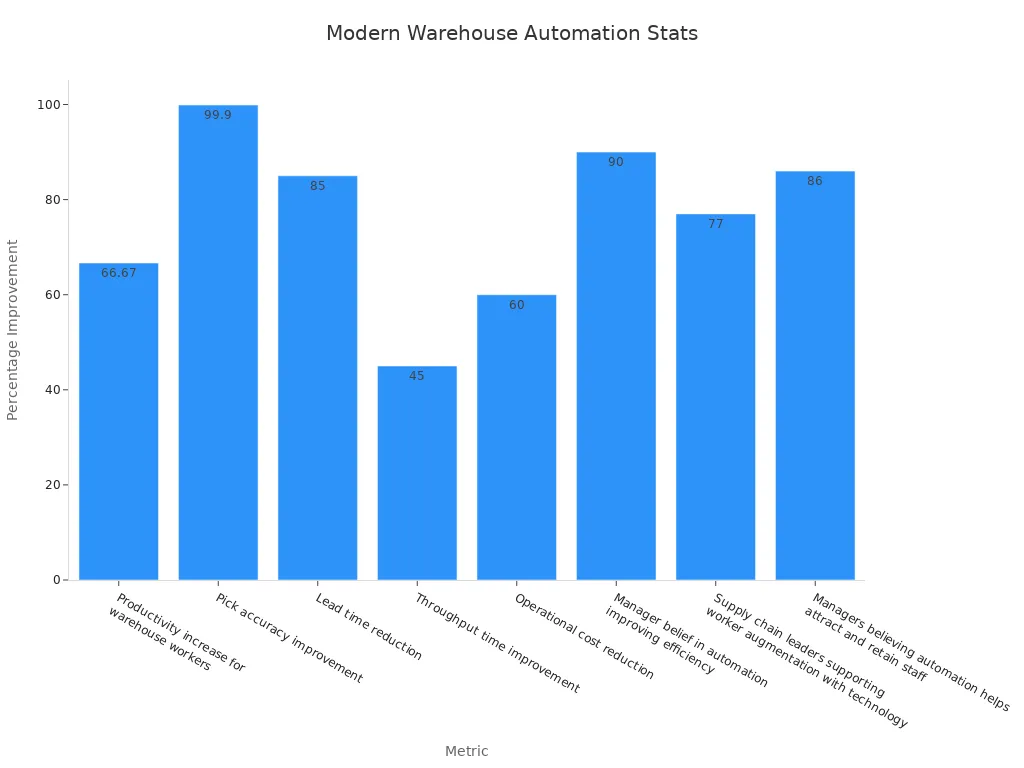

Order fulfillment automation transforms your warehouse. Automated order fulfillment systems use robots and conveyors to speed up picking and packing, reduce errors, and scale with demand.

Metric | Improvement/Statistic | Source |

|---|---|---|

Productivity increase for warehouse workers | Karadex | |

Pick accuracy improvement | Up to 99.9% | Karadex |

Lead time reduction | 85% | Bizagi |

Throughput time improvement | 45% | Bizagi |

Operational cost reduction | 60% | Bizagi |

You achieve automated accuracy, improved accuracy, and cost savings through optimization.

Advanced Reporting for Data-Driven Decisions

Advanced reporting gives you the insights to make smarter logistics decisions. Industry leaders using data-driven strategies see up to 15% higher ROI and 10% faster growth.

Source | Evidence Type | Key Findings |

|---|---|---|

Gartner (2023) | Industry Analytics Report | Predicts >75% of commercial supply chain apps will embed advanced analytics and AI by 2026. |

McKinsey (2023) | Industry Analytics Report | Early adopters of supply chain analytics outperform peers by 15% ROI and 10% growth. |

Walmart (Bernard Marr, 2018) | Case Study | Achieved 14% better on-shelf availability, 30% inventory cost reduction, 60% faster response. |

Capgemini (2022) | Industry Analytics Report | Logistics firms using advanced analytics report 25% higher Net Promoter Score. |

UPS (2022) | Case Study | Uses data analytics to optimize delivery routes considering 200,000+ alternatives per delivery. |

YQN Smart WMS delivers seamless system integration, real-time visibility, and unmatched fulfillment performance. If you need 3pl warehouse services in North or South America, or want a free consultation, contact info@yqn.com.

Future Plans for Intelligent Recommendations in YQN WMS

Intelligent Dock Assignment for Inbound Vehicles

You will soon benefit from intelligent dock assignment in your 3pl warehouse. The system will analyze inbound vehicle schedules, current dock usage, and real-time traffic inside the facility. This approach ensures you assign each truck to the best dock, reducing wait times and speeding up fulfillment. Automated storage and picking systems will further streamline your logistics, making your warehouse more efficient.

Smart Workforce Scheduling and Labor Saturation Management

You can expect YQN Smart WMS to introduce AI-driven workforce scheduling. The system will use real-time data and predictive analytics to balance labor saturation. You will assign tasks based on order volume, worker skill, and fulfillment urgency. Voice picking technology and industrial IoT devices will guide your team, increasing productivity and accuracy in your 3pl operations.

Optimized Packing Strategy Recommendations for Outbound Orders

You will receive optimized packing strategies for every outbound order. The system will recommend the best packing materials and methods, considering SKU size, order type, and delivery requirements. Robotic arms and AI-powered analytics will automate packing, reduce waste, and improve fulfillment speed. This innovation supports your 3pl business as you scale in the competitive logistics market.

YQN’s Smart WMS solution offers seamless scalability and operational flexibility—ideal for businesses navigating growth and complexity. Designed to enhance inventory accuracy and streamline workflows, it helps improve customer satisfaction while positioning your supply chain for long-term success. Whether you're managing logistics in North or South America, YQN Logistics provides reliable warehouse services and expert support. For more information or a free consultation, contact info@yqn.com.

FAQ

How does YQN Smart WMS improve warehouse efficiency?

You use intelligent recommendations to optimize palletizing, putaway, and picking. The system reduces manual errors and speeds up order fulfillment.

Can YQN Smart WMS integrate with my existing systems?

You can connect YQN Smart WMS with most ERP, TMS, and e-commerce platforms. Integration ensures seamless data flow and real-time visibility.

Where can I get more information or a free consultation?

For North or South America warehouse services or a free consultation, contact info@yqn.com. YQN logistics supports your business growth with smart 3PL solutions.

See Also

How Automation Enables YQN Warehouse To Process Thousands Hourly

YQN Presents Advanced Digital Logistics At Intermodal South America

Enhancing Global Logistics For Top Warehouse Robotics Company

Boosting Supply Chains Through Efficient Data Center Logistics

Important Changes Cross-Border Sellers Should Understand About US Warehouses

Shipping with YQN - Global Logistics at Your Fingertips

YQN has established subsidiaries worldwide, covering North America, Latin America, Southeast Asia, and the Middle East. We have partnered with 300+ top shipping and airline companies and have access to 3500+ high-quality supplier resources. YQN also has a professional customer service and fulfillment team of over 500 people to provide more worry-free and efficient international logistics services.

Contact Us

You can also email us at info@yqn.com.